5 Advantages of Thermal Insulation Coatings

When it comes to insulation, unfortunately, we do not have an abundance in choice. For instance, glass wool insulates both temperature and dampens noise; however, it lacks anti-corrosion properties and requires considerable space. Moreover, in some cases, it even functions as a sponge for water, mold, and insects. On the other hand, although polystyrene is light and easy to apply, it lacks anti-corrosion properties. There are special sound-proof and thermal insulating forms available, but are expensive, anti-corrosive, and cannot combat the challenges cold and heat in one solution.

Fortunately, the developments in micro and nanotechnology during the nineties and the zero years did not bypass the insulation market without notice. Today, high-performance insulating coating uses micro-sized materials with Nano-size internal architecture that inhibits heat transfer, thus causing the material to act as an effective thin insulator – inside or out, and even when sandwiched between other materials. As the coating can penetrate the intricate intermolecular structure of materials like steel and synthetics, it bonds with the surface and offers robust anti-corrosive characteristics and unmatched tear-off rates. These attributes are indispensable in maritime and industrial environments.

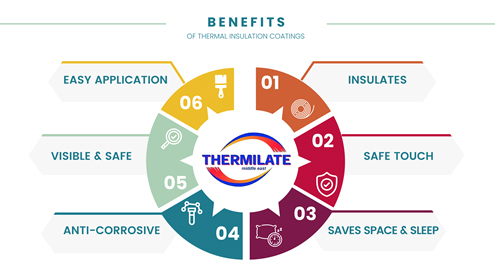

Now, how does that help us on board our vessels? Take five:

- Insulates: Remember the cost of heating HFO-lines? Or the diesel for keeping suites warm? Or keeping the bridge cool? One of the significant benefits of thermal insulating coatings is that it reduces heat loss on our lines as it covers the entire area. Yes, that includes the tight bends in small corners, the hard-to-reach tubes between machinery, and the lines running under the floor. Thermal insulating nanotech coatings can significantly reduce heat transfer and lower energy costs.

- Safe Touch: Thermal insulating coating certainly enhances safety in the engine room. With only ten coats, the line temperature is reduced from 150C/302F to 66C/152F. Whereas, on a steam pipe and water-cooling pipes, it is reduced to 47C/118F level.

- Saves Space & Sleep: The cladding in the engine room requires you to ascend and descend small steps and ladders. Bumping one’s chest and back against the wider-than-expected cladding causes unnecessary bending/denting of cladding and tubes. This then disturbs one’s balance and forces them to take a long way home. And imagine… a 15-centimeter wider bed!

- Anti-Corrosive: The micro and Nanoparticles like Hydro-NM-Oxide build a matrix into the metal surface, thus packing the intermolecular space. Thus, blocking water, oxygen, enzymes, acids, and other catalysts of corrosion. Several corrosion tests reveal how thermal insulating coatings combated severe environments that are usually notorious for causing corrosion. Also, the chemical resistance of a few thermal insulating coatings adds to its anti-corrosive properties.

- Visible & Safe: Whoever have stripped down cladding or glass wool insulation to look for a leak knows the mess it creates, and the expenses involved. However, the thermal insulating coatings (especially the translucent one) allows us to keep a close check on the system. Which means, no surprise rust, no unidentified cracks, and unrestricted access to inspect the metals when required.

- Bonus – The Application: Throughout the years, a frequently asked question regarding thermal insulating coating is its application. Painting is usually an easy task, and thermal coatings are commonly applied like paint. Therefore, it certainly reduces labor and cost that often comes along with cladding and insulating with old fibrous materials.

But does that mean we bid farewell to old cladding and glass wool? No. Sound reduction and temperature over 204C/400F are beyond the scope of these coatings. However, if improving the safety and functionality of the engine room is your priority, then nanotechnology is the way to go.