What’s Rust? Why Do Metal Roofs Get Rust?: A blog about your situation and how you can fix it.

Metal roofing is a commonly used material on the commercial building market. It gives the roof a unique and attractive appearance to fit any style and budget. Vinyl, metal asphalt, metal standing seam, and corrugated metal roofing are some of the many common types.

Metal roofs also encompass a variety of standard shapes and styles. Regardless of the shape of your building or its dimensions, metal roofing installations can withstand any climate. However, with this type of material comes certain conditions that can lead to rust with time. There are definitely tips on roof maintenance in UAE and precautions that one has to take so that your metal roofs will give off their best performance for a long time.

What’s Rust?

Rust is a thin, reddish iron oxide coating that forms on iron and iron-based metals when they are exposed to moisture. Over time, the oxide coating can become thicker and thicker, until it completely covers the metal. This can lead to several problems, including:

- Reduced strength of the metal due to loss of its protective coating (oxidation).

- Increased weight of the object due to waterlogging and corrosion products (rust) on its surface.

- Increased cost of maintenance due to regular application of paint or other protective coatings required to keep the object looking good.

There are two types of rust: auto-oxidation and electro-chemical reaction (also known as galvanic corrosion). Auto-oxidation arises from oxygen in the atmosphere reacting with iron or steel surfaces. Electro-chemical reaction occurs when two different metals are in contact with each other, such as steel and aluminium or copper and zinc.

What Causes Rust?

The presence of oxygen in the atmosphere allows metals to oxidise when exposed to water or moisture. When it rains or snows, water seeps into the pores and crevices of a building’s exterior surfaces. If a building has an iron component like a metal roof or siding, then the moisture causes iron oxide (rust) to form on these surfaces as well as inside them as well. This happens because iron oxidises more easily than other metals like aluminium and stainless steel do.

Iron is oxidised by oxygen in the air and water molecules to form ferric hydroxide:

Fe + O 2 + H 2 O → Fe(OH) 3

As you can see above, this reaction also produces hydrogen gas — which explains why shallow puddles of water on wet metal roofs lead to rust stains. Once it oxidises, rust can spread quickly throughout your facility’s metal roofing and siding panels, creating unsightly stains that detract from your building’s curb appeal and value.

The rate of rust formation depends on several factors:

Weather—Weather is the biggest factor when it comes to rusting your metal roof. If you live in a region that gets lots of rain or snow, then your roof will be more susceptible to rusting. The sun also plays a role in this because the hotter the temperature, the faster the rusting process, which leads to more moisture buildup and increases the likelihood of rust appearing on your roof.

Moisture Buildup—Moisture buildup is another reason why metal roofs get rust. If there’s too much moisture on your roof, then it could lead to corrosion because moisture causes oxidation — which means that oxygen combines with another element (typically iron) to form an oxide compound called iron oxide (rust). The more moisture there is on your roof, the worse it will get over time because more oxygen will be available as a catalyst for this process to occur. Water can also cause other problems for metal roofs by corroding them from within through tiny holes in the paint or sealant coatings.

Rust forms on these surfaces:

Pipes or tubes. Rusting occurs when water seeps into the pipe, combines with oxygen, and then turns into a type of iron oxide called rust. As the water evaporates, it leaves behind the iron oxide that becomes visible as the rusty pipe.

Metal roofing or gutters. When rainwater soaks into the roofing material, it combines with oxygen to form pollutants that react with metals in the roofing materials. This causes corrosion in metal roofs over time.

Metal warehouse buildings and sheds. Metal storage buildings are subject to corrosion from pollution in the air, which causes oxidation in metal surfaces such as steel doors and window frames.

How Do You Fix A Rusty Metal Roof?

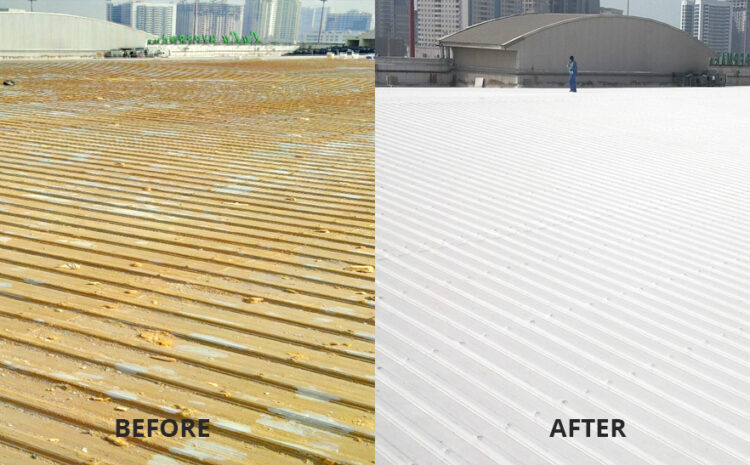

Rust arrestor coating:

A good way to prevent rust on your metal roofing is by using a rust arrestor coating. This coating chemically transforms rust into its original form, halting the formation of new rust so that it can’t spread through your entire surface. There are many different types of rust arrestor coating available for use on all types of metals including steel, aluminium and galvanised steel. Some types may even be sprayed directly onto the area where there is already existing rust forming. A very useful method for preventing further rusting, especially on large areas such as industrial buildings or warehouses.

Inspect and repair leaks or holes on metal roofs.

The best way to prevent rust on your metal roofing is to maintain it properly. An inspection of the condition of your metal roof should be done annually. If you have a leak in your metal roof, it’s important to repair the problem as soon as possible to prevent further damage and rust. The longer you wait to fix a leaky roof, the more likely rust will form and spread across your entire surface. A leaky roof should be fixed immediately before water enters your facility and causes more damage.

A professional roofer can inspect your roof for damage, leaks and other problems with our state-of-the-art equipment. Repair any damage immediately to prevent further damage from occurring.

Clean gutters

Gutters are the first line of defence against water damage, so getting them in good shape is essential. First, inspect the gutters for any holes or other damage. Next, clean out any debris that might be clogging them up. Make sure to use a soft brush and a hose to avoid damaging the metal itself.

The fabrication and repair of flashing and gutter for the roof.

After cleaning out your gutters, Make sure all flashing (the metal that goes around openings such as chimneys) is in good condition. Flashing is especially important because it helps prevent leaks from occurring between where your roof meets another surface like a wall or window frame. If it’s damaged or missing, install new pieces of flashing or gutter guards. Also make sure the gutters have no holes and are securely attached to the roof.

Rust Bullet coating

Rust Bullet application is the best method to fix rust on metal roofs. Rust Bullet is an anti-rust sealer that can be applied on the metal roofing surface and will protect it from rusting. It can be applied over the existing coating or directly on top of the bare metal.

Rust Bullet can also be used on other metals such as iron, steel and aluminium. This product has been tested by the EPA and meets their requirements for lead-free compliance. Even if you’ve tried other rust treatments before and had mixed results, Rust Bullet may be worth another shot.

The Good News About Metal Roofing and Rust

Metal roofs have been around for more than a hundred years. They’ve been used on homes, warehouses, barns and other industrial buildings. The fact that they’ve been around for so long means that there are lots of examples of metal roofing systems in good condition.

The fact that metal roofs have been around for so long also means that there are many different types of metal roofing systems available today. Some are better than others at resisting rust and corrosion.

The best way to find out which type of metal roofing is right for your facility is to talk with a professional roofer who specialises in metal roofing systems. You’ll want someone who knows all the options available to you and can help you choose one that fits your needs and budget.

Get a professional assessment of your metal roof

If your metal roof is getting rusty, get a professional assessment of your roof situation. It’s very hard to see the extent of the damage when it happens on or in your home or property. Damage can cause leaks and water infiltration in your structure and make you susceptible to mould due to mildew. Thermilate roof contractors will get your metal roof checked by and supply you with reliable metal roof waterproofing coatings Dubai, give us a call at +971 4 2511 390.

Contact us today for a FREE roof evaluation and get a detailed roof report from us. Our waterproofing team will inspect the roof home and provide you and provide you a working solution, including a written contract that spells out each detail for you, without any hidden agendas.